Crossrail station Canary Wharf

Sturdy and light at the same time

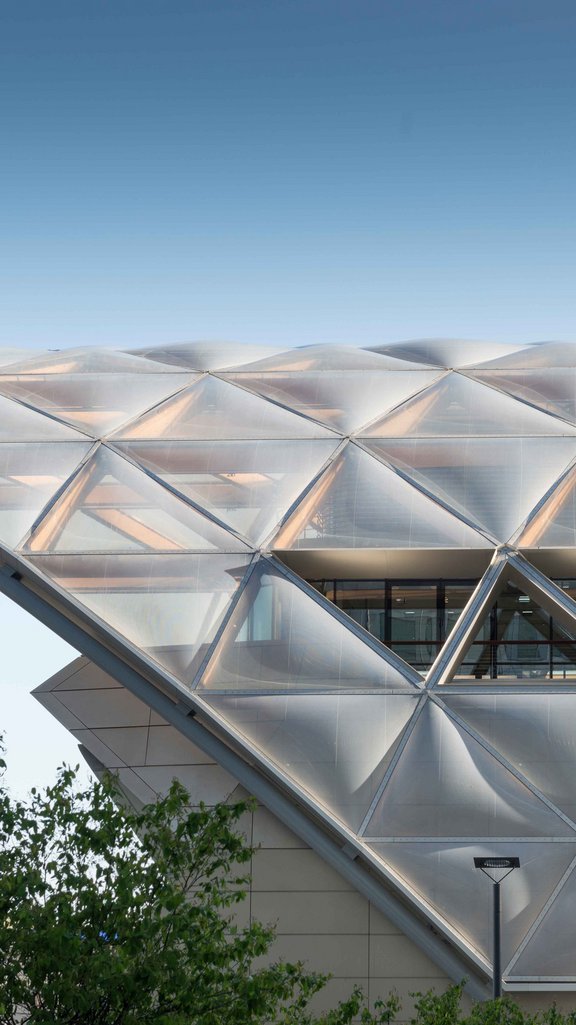

The fully submerged station is located in the North Dock, serving as a link between the Canary Wharf Estate and Poplar to the north. The challenge: The station had to lie 18 metres below the water level, take the weight of the Crossrail Place development above it and be robust enough to withstand the impact of ships. The roof had to be light and airy to avoid adding unnecessary weight, but also provide shelter for the public rooftop garden located on the top floor.

![[Translate to Englisch:] Crossrail Station Canary Wharf [Translate to Englisch:] Crossrail Station Canary Wharf](/fileadmin/_processed_/9/c/csm_wiehag-crossrail-canary-wharf-10_5c100792af.jpg)

A filigree roof construction

1,000 cubic metres of PEFC-certified timber from local, sustainable forestry were processed into 1,414 wooden beams at the state-of-the-art manufacturing plant in Altheim. In March 2014, after a six-month production phase, the ready-to-assemble individual parts were assembled into a 300-metre long roof structure. The infrastructure of the Canary Wharf station and the entire Crossrail line were completed in 2018.

![[Translate to Englisch:] Crossrail Station Canary Wharf [Translate to Englisch:] Crossrail Station Canary Wharf](/fileadmin/_processed_/c/8/csm_wiehag-crossrail-canary-wharf-03_7e7c6a8a68.jpg)

The construction details

- 300-metre long roof construction

- 1,000 m³ of PEFC-certified wood

- 1,414 timber beams, 4 of which are curved

- 72 steel girders

- 564 steel nodes, 86 of which connect to reinforced concrete

- 2 double-curved ring-beams at the roof cantilever edges to the east and west

![[Translate to Englisch:] Crossrail Station Canary Wharf [Translate to Englisch:] Crossrail Station Canary Wharf](/fileadmin/_processed_/d/9/csm_wiehag-crossrail-canary-wharf-12_faadd78385.jpg)

Timetable and budget of the Crossrail line

Construction of the 100 km long Crossrail line from Maidenhead to Shenfield & Abbey Wood began in May 2009. The entire Crossrail infrastructure project, including the station at Canary Wharf, was opened in 2018. The construction cost is estimated at approximately 18 billion euros. Canary Wharf cost over 600 million euros. When completed, the railway line will connect Heathrow Airport with the east of London.

![[Translate to Englisch:] Crossrail Station Canary Wharf [Translate to Englisch:] Crossrail Station Canary Wharf](/fileadmin/_processed_/b/b/csm_wiehag-crossrail-canary-wharf-11_5f7f04ab10.jpg)

- Location

- London (GB)

- Client

- Canary Wharf Contractors Ltd.

- Architecture

- Foster + Partners, London

- Services provided/type of construction

- Planning, structural analysis and production of the roof support structure

![[Translate to Englisch:] Crossrail Station Canary Wharf [Translate to Englisch:] Crossrail Station Canary Wharf](/fileadmin/_processed_/8/c/csm_wiehag-crossrail-canary-wharf-04_d09ab6716a.jpg)

![[Translate to Englisch:] Crossrail Station Canary Wharf [Translate to Englisch:] Crossrail Station Canary Wharf](/fileadmin/_processed_/b/5/csm_wiehag-crossrail-canary-wharf-07_910a587b70.jpg)

![[Translate to Englisch:] Crossrail Station Canary Wharf [Translate to Englisch:] Crossrail Station Canary Wharf](/fileadmin/_processed_/b/b/csm_wiehag-crossrail-canary-wharf-11_9bb23cfba9.jpg)

![[Translate to Englisch:] Crossrail Station Canary Wharf [Translate to Englisch:] Crossrail Station Canary Wharf](/fileadmin/_processed_/7/7/csm_wiehag-crossrail-canary-wharf-05_3f83ae013f.jpg)

![[Translate to Englisch:] Crossrail Station Canary Wharf [Translate to Englisch:] Crossrail Station Canary Wharf](/fileadmin/_processed_/f/0/csm_wiehag-crossrail-canary-wharf-06_7fcbab1f6d.jpg)

![[Translate to Englisch:] Crossrail Station Canary Wharf [Translate to Englisch:] Crossrail Station Canary Wharf](/fileadmin/_processed_/b/8/csm_wiehag-crossrail-canary-wharf-08_417888f282.jpg)

![[Translate to Englisch:] Montage Crossrail Station Canary Wharf [Translate to Englisch:] Montage Crossrail Station Canary Wharf](/fileadmin/_processed_/c/8/csm_wiehag-crossrail-canary-wharf-03_f63bb7b380.jpg)

![[Translate to Englisch:] Crossrail Station Abbey Wood [Translate to Englisch:] Crossrail Station Abbey Wood](/fileadmin/_processed_/3/9/csm_wiehag-abbey-wood-crossrailstation-09_2f9161eb3f.jpg)

![[Translate to Englisch:] Freemen's School Pool Innenansicht [Translate to Englisch:] Freemen's School Pool Innenansicht](/fileadmin/_processed_/1/8/csm_wiehag-freemens-school-pool-05_200f04f0e9.jpg)

![[Translate to Englisch:] St. Georges College Activity Center [Translate to Englisch:] St. Georges College Activity Center](/fileadmin/_processed_/c/9/csm_st-georges-college-activity-center-4_a6fe918fec.jpg)

![[Translate to Englisch:] University of Birmingham Teaching Building [Translate to Englisch:] University of Birmingham Teaching Building](/fileadmin/_processed_/6/c/csm_university-of-birmingham-teaching-building-2_3a3faa7c40.jpg)

![[Translate to Englisch:] Macallan Destillerie [Translate to Englisch:] Macallan Destillerie](/fileadmin/_processed_/d/f/csm_wiehag-macallan-distillery-67_734c37af51.jpg)

![[Translate to Englisch:] Baumturm am Grünberg [Translate to Englisch:] Baumturm am Grünberg](/fileadmin/_processed_/d/9/csm_wiehag-baumturm-am-gruenberg-01_623f51f8bc.jpg)

![[Translate to Englisch:] ÖBB Rail-Service-Center Wien [Translate to Englisch:] ÖBB Rail-Service-Center](/fileadmin/_processed_/b/b/csm_wiehag-oebb-rail-service-center-wien-2_33df911427.jpg)